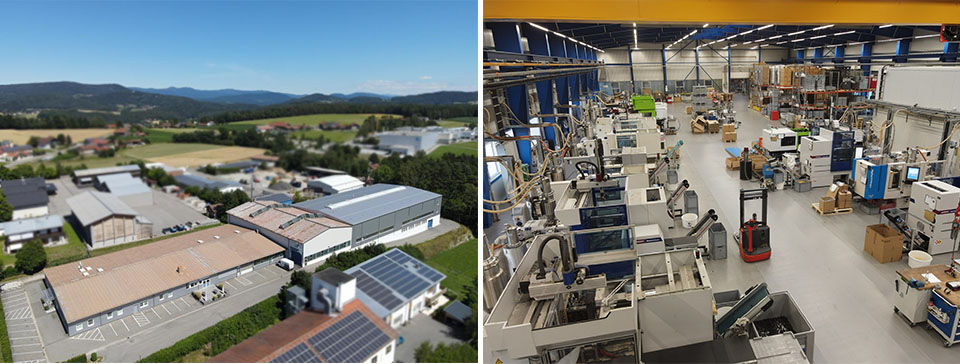

Growing customer demands and the need to expand production capacity prompted WeForm, based in Viechtach, Lower Bavaria, to consider 5-axis HSC (high-speed cutting) milling and automation as part of an expansion of its production area. The company ultimately decided to invest in a fully automated production cell.

Cimatron CAD/CAM software, which WeForm had used for tool and die production for two decades, supplies the cell with NC programs, erosion parameters, and measurement coordinates.

WeForm supplies a wide range of industries with high-quality plastic injection molded and zinc die-cast parts. Among industries served are the toy, packaging, orthopedic technology, and telecommunications sectors, and counted among its variety of customers are electrical and mechanical engineers.

The company’s in-house toolmaking department, which employs the majority of WeForm’s approximately 50 employees, manufactures injection molds and die-casting molds, including multi-cavity molds with up to 60 cavities and multi-component molds in rotary table design, for in-house production and external customers.

It also produces graphite electrodes and components for stamping tools as a contract manufacturer, as well as machined components using 3- and 5-axis milling technology, and wire and die-sinking EDM. As an expert in tool and moldmaking, as well as plastics processing and zinc die casting, WeForm supports its customers from part development to series production and offers tailor-made solutions for demanding projects.

The introduction of a fully automated production cell was a major investment for WeForm, as the planning and implementation costs were a factor that could not be underestimated.

The increasing demands of our customers and an exceptionally good order situation made it necessary to expand our production capacities and invest in new 5-axis milling technology.

“It was obvious to think about automation because we did not want to deviate from our single-shift operation and had to utilize the new machine as fully as possible. We discussed a wide range of concepts with several suppliers — from individual automation through to linking several machining operations and technologies in one system."

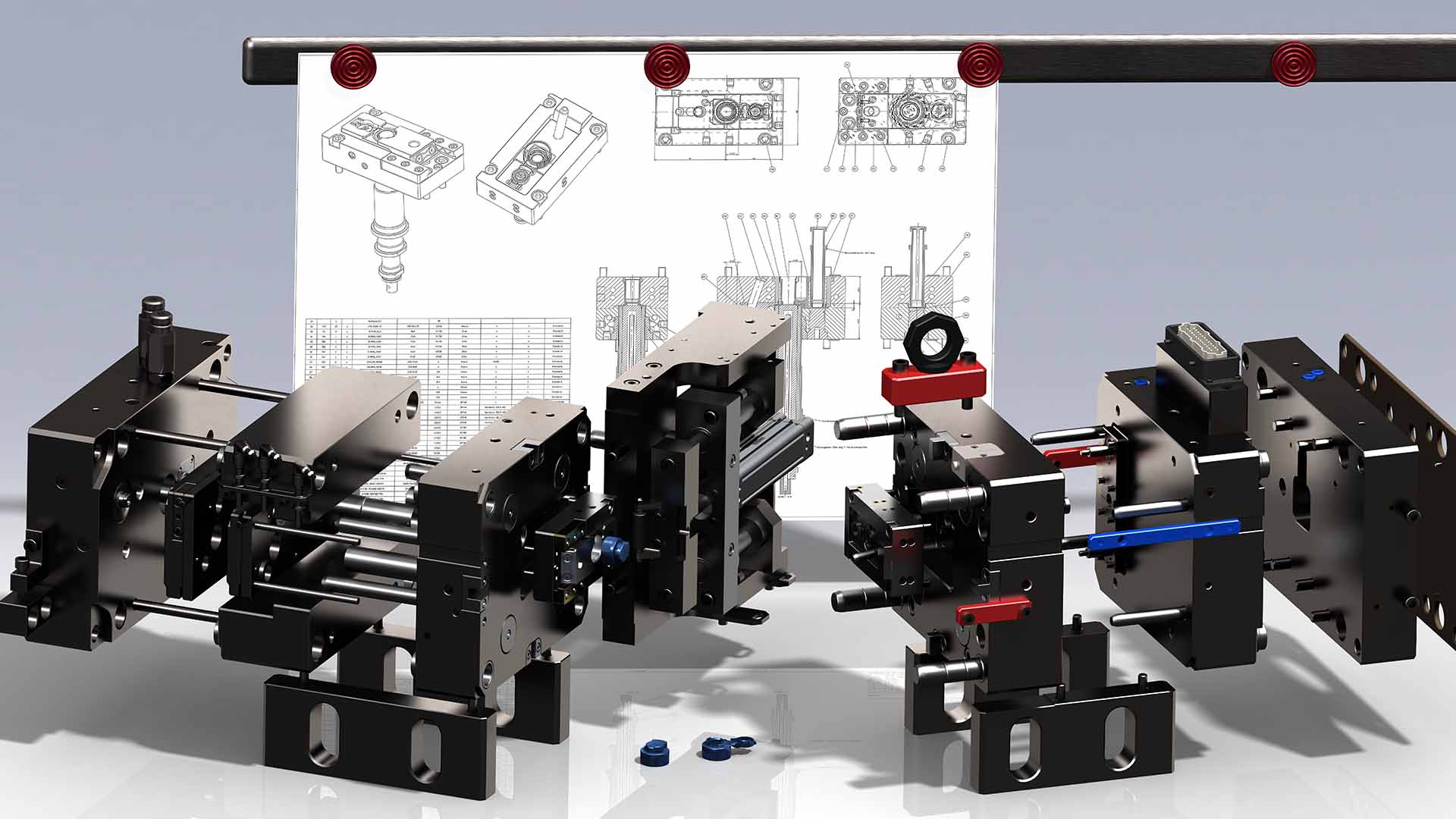

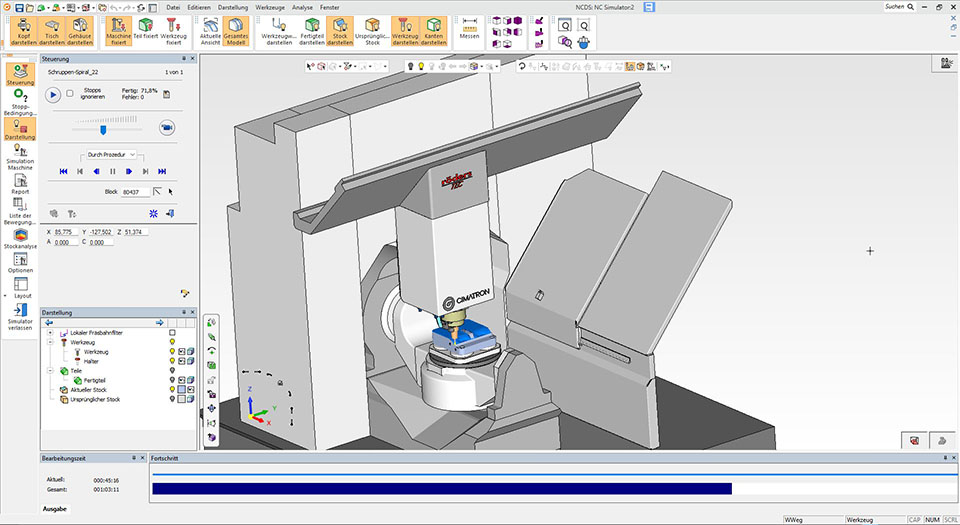

The idea behind the system is to combine several work steps — depending on the degree of automation up to the finished measured part — in one system by using a robot to supply different production modules with workpieces, electrodes, and milling tools.

At WeForm, the cell consists of two Röders milling machines, a Zimmer & Kreim die-sinking EDM system, a loading station, a Zimmer & Kreim washing system, and a Mitutoyo measuring machine.

In addition, the cell has a storage capacity for up to 850 electrodes and 24 workpiece pallets with a Partool clamping system. Pallets and electrode holders are equipped with RFID chips from Zimmer + Kreim to ensure continuous data availability.

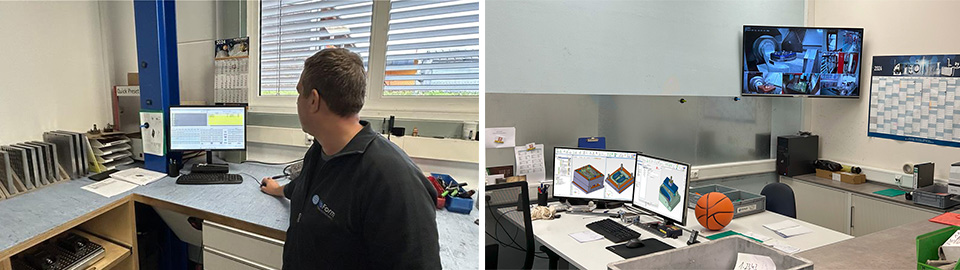

When the system was installed, a complete air conditioning system and video surveillance with a total of six cameras were also installed, allowing the entire cell to be monitored from anywhere.

Andreas Wilhelm monitors production processes outside the cell via a terminal (left). In theory, the doors only need to be opened to load and unload the cell. Camera monitoring allows the cell to be monitored live via large monitors in the work preparation department (right).

"For us as a company that works in single-shift operation and has to create additional production capacity in unmanned operation, automation is the key to success," summarizes Freundorfer.

"We achieve significantly higher efficiency and productivity when we also operate our machines at night and on weekends. In addition, well-planned automation offers us significantly increased flexibility. In Zimmer & Kreim, we found a partner who had the necessary experience to successfully implement the complex implementation with us."

And WeForm has a similarly successful partnership with the CAD/CAM specialists from Cimatron. WeForm entered the CAD/CAM field over 20 years ago with the CAM and electrode solution from Cimatron.

Andreas Wilhelm, managing director, looks back on that time: "Of course, we also looked at other CAD/CAM solutions from time to time to see what was possible with others. Ultimately, we have stayed with Cimatron to this day because the overall package is ideal for our application. Even if there are requests for improvement here and there on our part, we don't currently see any other software that offers tool and moldmaking at a comparable level of consistency. We also feel that we receive excellent support from the Cimatron team. Thanks to Cimatron's focus on our industry, we can find the right contacts there for all our questions and requirements."

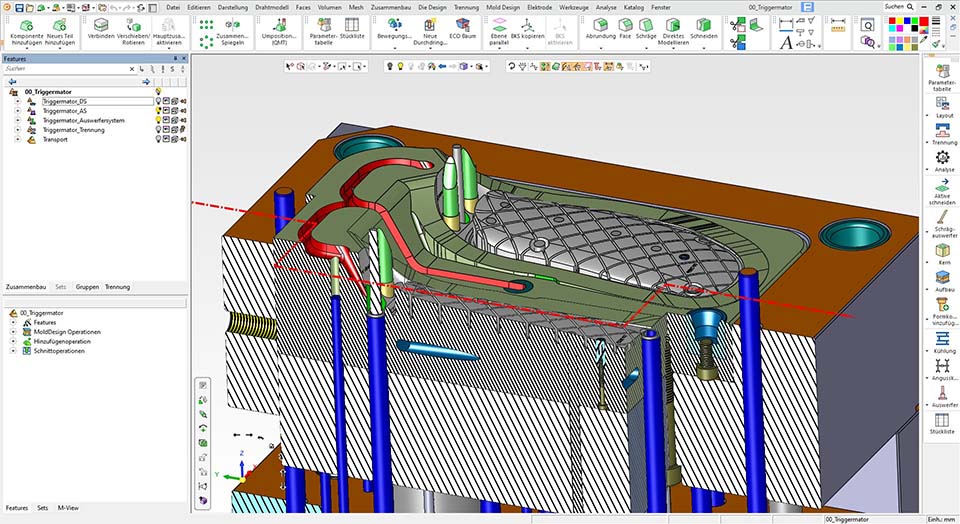

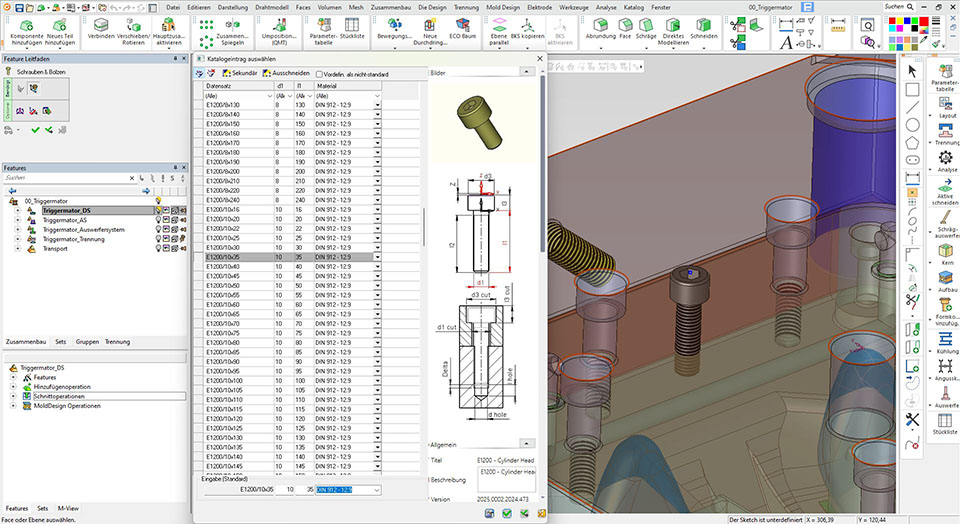

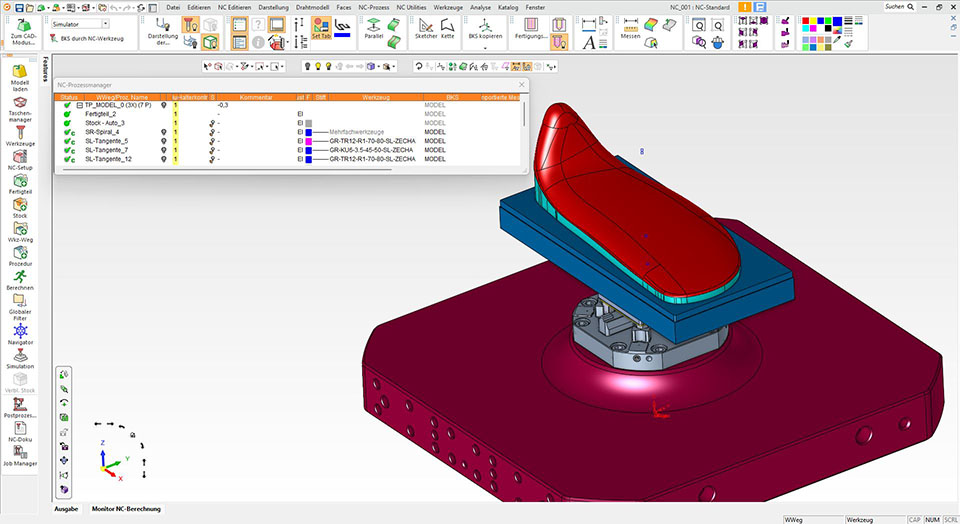

WeForm uses Cimatron throughout, from data import and tool-compatible preparation of the article data from the customer to tool design, electrode creation, and transfer of milling programs to the two Röders machines. Cimatron is also responsible for transferring the erosion parameters to the Zimmer+Kreim software and providing measuring points for the measuring machine.

Thanks to the consistent Cimatron application, there is no interface between CAD and NC programming and there is no need to manually enter coordinate points for measuring and eroding or to manually record all other eroding parameters. Possible sources of error are therefore eliminated from the outset and time and costs are saved.

"We have to produce on the Chameleon as continuously as possible in order to justify the investment in this high level of automation. It is therefore vital for us to eliminate potential sources of error in advance. Manual intervention in the process must be avoided. Cimatron provides the cell with exactly the quality and quantity input that we need to manufacture quickly and efficiently and to utilize our Chameleon to capacity," explains Wilhelm.

A mold for an orthopedic application is an example of a project that underwent this process at WeForm.

"With Mold Design, Cimatron offers us a complete tool that takes all aspects of mold design into account,” Wilhelm says. “Starting with the mold separation, determination of the demolding directions, the creation of the parting surfaces, the generation of the mold inserts, the selection of all catalog parts through to the ejector package, the cooling system and the sprue, you are guided safely through the entire mold design."

When asked whether Cimatron not only makes tool and moldmaking at WeForm more efficient but also more sustainable, Wilhelm answers: "Cimatron helps us to achieve our goal of working error-free. Fewer errors mean fewer rejects. This not only saves time for new production or repair, but also material and energy. In this respect, Cimatron also allows us to manufacture more sustainably."

Website WeForm: www.weform.de

WeForm, responding to growing customer demands, invested in a fully automated production cell integrating 5-axis HSC milling and Cimatron CAD/CAM software for efficient production of high-quality plastic and zinc die-cast parts across various industries.

Everstampi, a family-owned company in Misinto with more than 40 years of experience in plastics mold design, stands out for its innovation and focus on customer service, using CAD/CAM solutions from Cimatron to optimize the production process and ensure complex, high-precision molds.

Classic Tool & Die, leveraging Cimatron's advanced CAD/CAM software, achieved a 75% productivity increase and reduced its carbon footprint, while successfully tackling challenging die design projects and fostering innovation with automotive OEMs.

A focus on electrode design and automation helps toolroom improve efficiency, reduce tooling costs and deliver higher quality products.

Clips & Clamps Industries efficiently handles complex die designs and high-volume production requirements by leveraging Cimatron CAD/CAM software, which streamlines workflows, optimizes designs, and enables significant cost savings through material optimization and enhanced tooling capabilities.

The integrated CAD/CAM software package from Cimatron helps TK Mold & Engineering Inc. reduce translation errors, simplify the design process, improve shop efficiency, and shorten tool lead times.

Follow us on