Everstampi is a 40-year-old family company specializing in designing, producing, and testing complex plastic injection molds. It uses the Cimatron CAD/CAM system to optimize its mold design and production, including 4-axis machining.

Meeting customers' needs is a requirement for any business, but Italian mold specialist Everstampi has proven over four decades that it isn't just any business.

"Our success is due to recognizing that superior customer service and innovation are the only business strategies worth pursuing," said Meghann Colombo, account manager at Everstampi and daughter of the company's founder. "We have always invested in staff training and the technologies of providers that see automation as the future of mold manufacturing."

Everstampi has grown in size and expertise through years of working with customers to perfect its know-how in the design, production, and testing of plastic injection molds, which are among the most challenging to produce.

Integrating innovative technologies and focusing on customer service has helped the company secure its place as a leader in manufacturing high-volume hot and semi-hot-runner injection molds, with production cycles among the lowest on the market.

"We respond to the complex needs of our customers with clarity, transparency, and precision every step of the way," Colombo said.

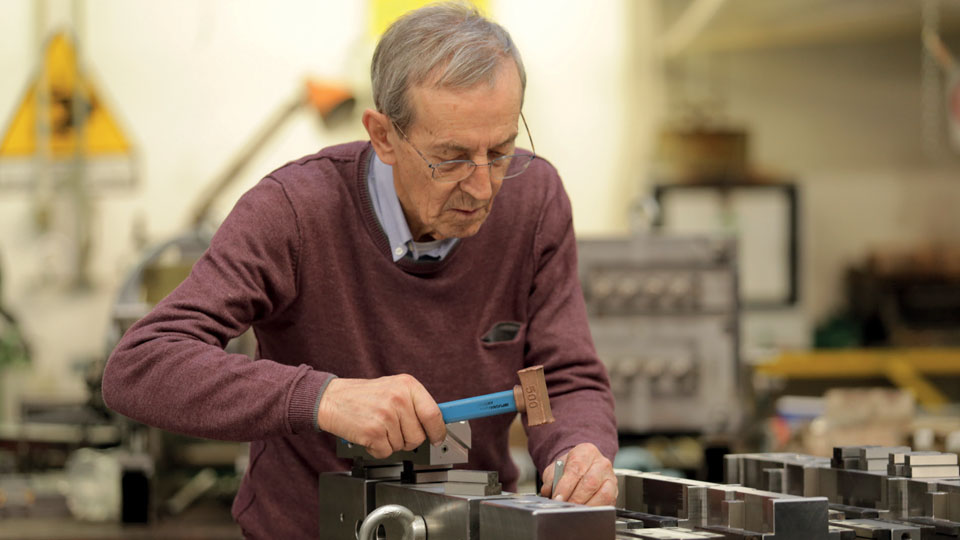

Everstampi was founded in 1983 by Mario Colombo, a skilled mold maker who struck out independently after gaining experience at various mold manufacturing companies.

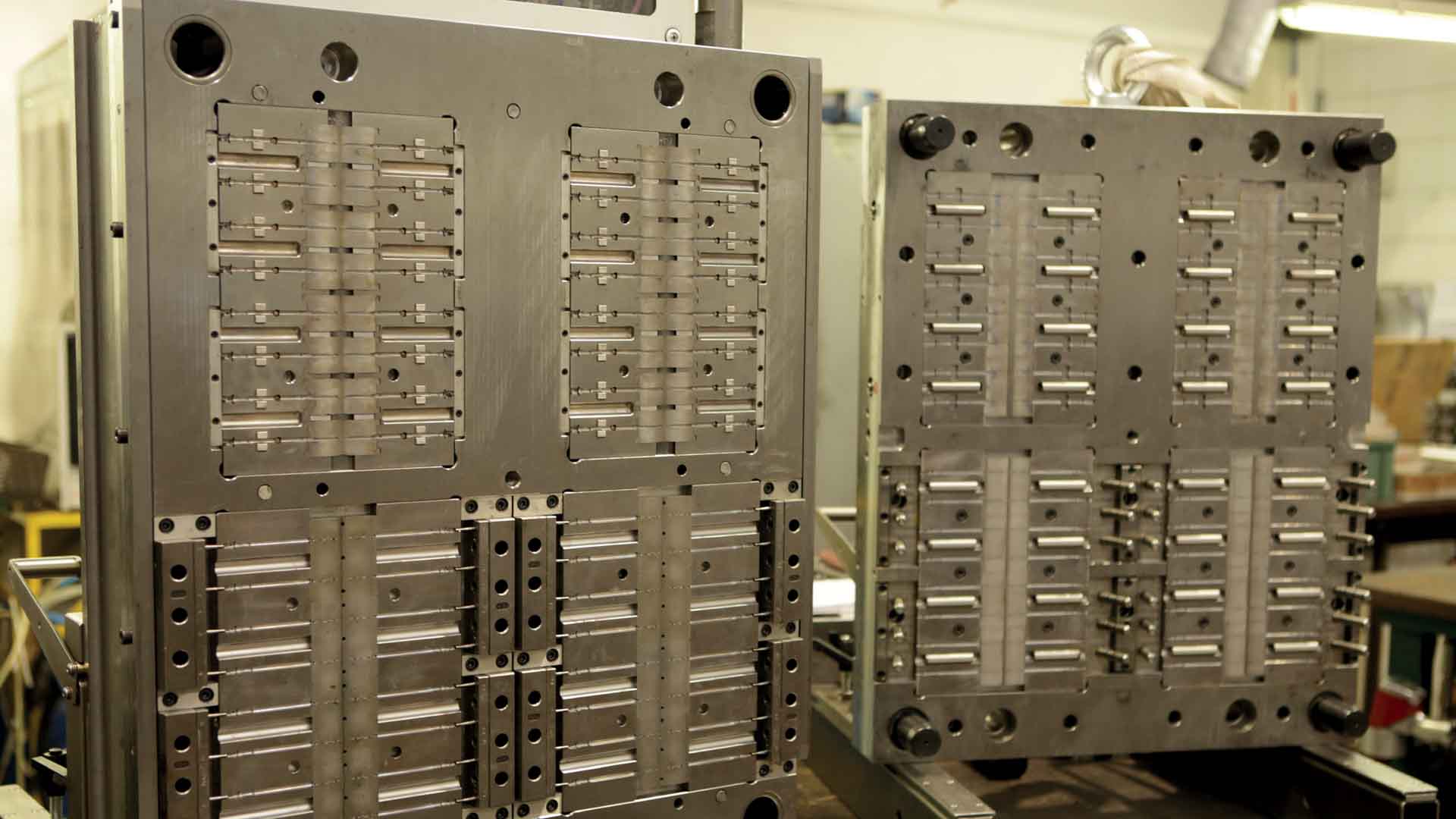

Today, the company is managed by his children, including Meghann, Jennifer, finance director, and Edoardo, production manager — though Mario can still be found on the shop floor. Throughout Everstampi's more than 40 years in business, the company has built over 700 molds and the possibility of creating molds with up to 128 cavities.

Based in Misinto—in the Lombardy province of Monza and Brianza—Everstampi builds tooling for leading Italian and foreign multinationals in multiple industries. It specializes in complex, high-precision molds for products such as actuators, spray caps, and dispenser pumps, as well as various products for the pharmaceutical, cosmetic, consumer, and technology sectors.

Everstampi recently built a tool to produce brushes for mascara, a particularly complex product to mold. The mascara applicator's exceptionally thin rubber bristles are challenging as the tiny and precise cavities must be created to meet exacting standards.

"Our greatest strength lies in our success with extremely challenging and complex projects, which sets us apart from the competition," said Edoardo Colombo. Experience with complex projects over the years enables the company to confidently perform HSC micro-milling with tools 0.2 millimeters in diameter, a challenging process that few companies in Italy can perform. Regardless of a job's complexity, the company guarantees customers that it will deliver on three fundamentals: precision, aesthetics, and functionality.

"Achieving precision and the customer's desired aesthetic for the final part is fundamental to producing the molds they need, and that begins with designs that fulfill those concrete requirements," said Edoardo Colombo. "The functionality of the mold is a result of carefully determining where and how to place components in response to the needs of injection, filling, cooling, and extraction."

Everstampi's tooling department houses six milling machines (3 and 5-axis), four EDM machines (two wire and two plunge), four lathes, four grinders, and a drilling machine capable of performing operations on molds with maximum dimensions of 1,000x800 millimeters. The company's metrology room maintains dimensional control of workpieces and guarantees that jobs meet quality requirements.

These in-house production and quality control capabilities streamline workflow while ensuring that critical processes take place on-site and are performed by the Everstampi team.

"We recently expanded the space dedicated to production with a new warehouse where we plan to use mold testing presses for tryouts — which until now was entrusted to an external partner company," said Meghann Colombo.

Another feather in Everstampi's cap is its customer service.

"Not only do we manage the maintenance of our molds, but we also maintain equipment made by other mold makers," said Meghann Colombo. "When collaborating with small businesses or large multinational groups, we always succeed in creating a relationship of mutual trust."

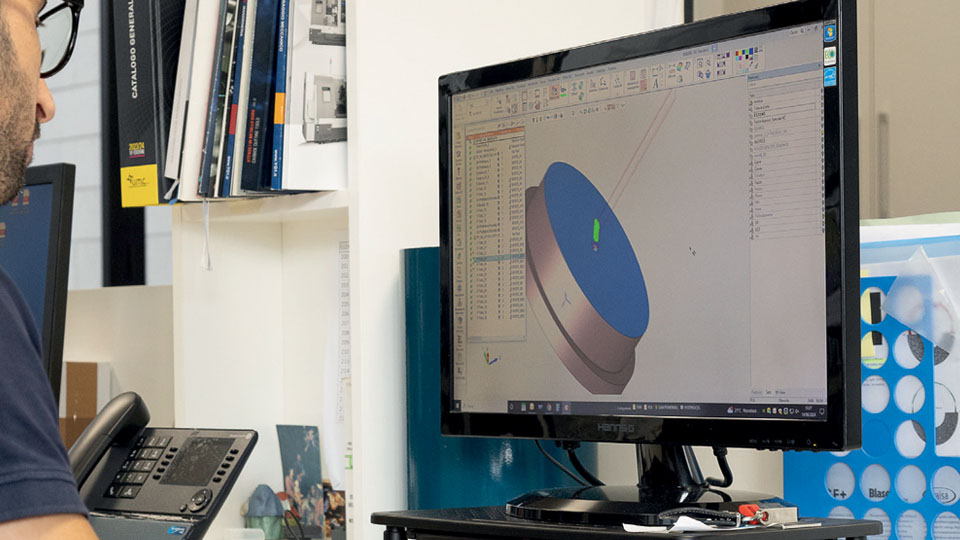

Jobs at Everstampi begin in the technical office, where its design team creates geometric models of complex molds derived from drawings or physical prototypes.

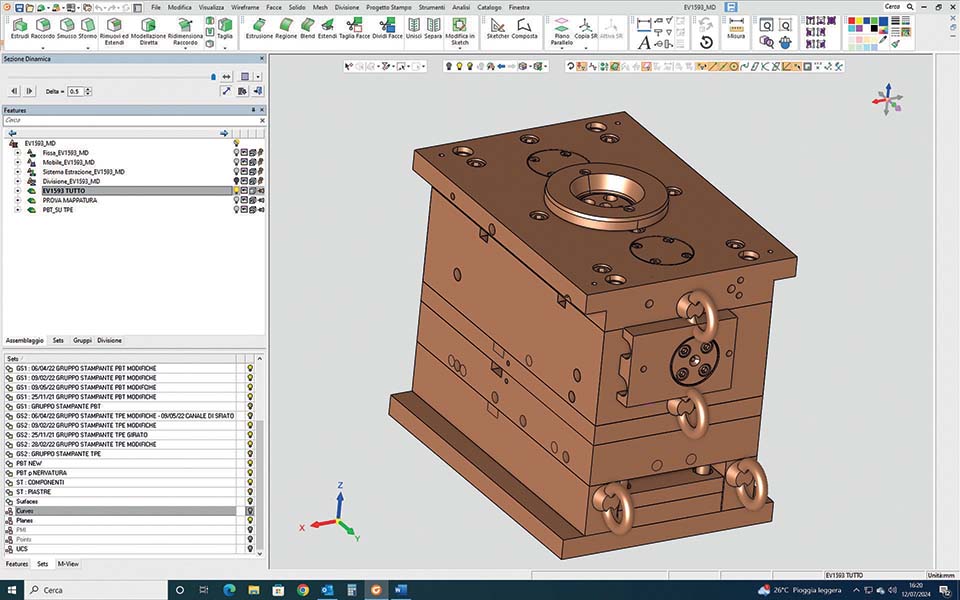

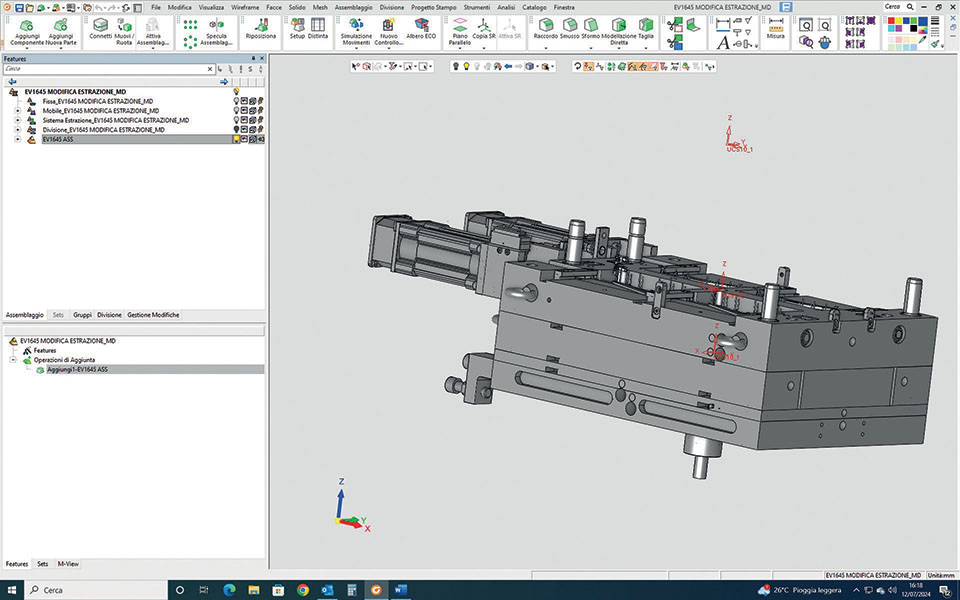

After choosing an approach to building individual mold components, computer-aided manufacturing (CAM) software generates the 3-axis and 5-axis toolpath needed to machine those components with CNC machinery. Everstampi has used Cimatron CAD/CAM software for about two years to optimize mold designs and generate CNC toolpaths.

"In the past, we used two different products for mold design and CAM programming, and dealing with completely separate systems took up a lot of time and energy," said Meghann Colombo. "We eventually decided to look around and see what else the market had to offer."

As Everstampi was already in contact with Cimatron Sales Manager Corrado Biggiogero, it was proposed that he help the company solve one of its biggest challenges: 4-axis machining operations that required a CAM operator to heavily intervene, increasing the opportunity for error, to achieve desired results.

"Thanks to Cimatron's integrated 4-axis machining, we significantly reduced programming and machining time while reducing the probability of error," said Edoardo Colombo.

Given the benefits gained from using Cimatron for CAM programming, the company extended its use to the software's CAD capabilities. "Thanks to Cimatron, we can now accomplish what we used to achieve with three different products with a single product and single interface; the efficiencies are clear," said Edoardo Colombo.

Cimatron CAD/CAM is dedicated software for mold design and production. It was developed from the outset to dramatically reduce lead times and help manufacturers optimize any CNC machinery, from 2 1/2-axis machines to advanced machining centers. It provides dedicated tools for each phase of mold development and production—from quoting and design to supplier component management and manufacturing.

The integration of CAD and CAM capabilities is of significant benefit to Cimatron users. This makes it possible to perform mold design and CNC programming within a single environment. To standardize processes and help companies consistently apply best practices, the software automatically captures and stores project data so that manufacturers can use information from previous jobs for new projects without the need to start all over again.

Offering ideal capabilities for less experienced mold makers, Cimatron includes built-in knowledge that automatically makes essential job parameter decisions. Due to its flexibility, the software's users can always edit automated parameters to reflect their preferences.

To ensure that jobs will be safely performed when sent to the shop floor, mold makers use Cimatron's cutting simulation and toolpath verification capabilities to ensure that components will be machined with a collision-free toolpath. This ability to verify job safety makes it easier to run machines unattended confidently for increased productivity.

Everstampi utilizes several advanced Cimatron software modules, for specific mold design tasks and for safely performing 3-axis, 3+2-axis, and 5-axis machining operations.

"We also rely on Cimatron Viewer, a solution that makes the verification process easier and ensures that everyone involved is working with the same data," said Edoardo Colombo. The management at Everstampi is satisfied with both the quality of the software and the post-sales service provided by Cimatron.

"We have found Corrado Biggiogero to be an extremely knowledgeable and professional partner who responds immediately to our needs," said Meghann Colombo. "An excellent dialogue has been established with him and his support team, which is an advantage that helps prevent numerous problems."

ComplexaHPE utilizes Cimatron CAD software to design intricate molds for the medical industry, enhancing efficiency and precision in producing complex tooling needed for various medical components.

Stevenson High School's MADE Program, in collaboration with Zero Tolerance and Cimatron, is training the next generation of manufacturers through hands-on experience and industry partnerships to address the skilled worker shortage.

WeForm, responding to growing customer demands, invested in a fully automated production cell integrating 5-axis HSC milling and Cimatron CAD/CAM software for efficient production of high-quality plastic and zinc die-cast parts across various industries.

Everstampi, a family-owned company in Misinto with more than 40 years of experience in plastics mold design, stands out for its innovation and focus on customer service, using CAD/CAM solutions from Cimatron to optimize the production process and ensure complex, high-precision molds.

Classic Tool & Die, leveraging Cimatron's advanced CAD/CAM software, achieved a 75% productivity increase and reduced its carbon footprint, while successfully tackling challenging die design projects and fostering innovation with automotive OEMs.

A focus on electrode design and automation helps toolroom improve efficiency, reduce tooling costs and deliver higher quality products.

Follow us on