Long, manual process for designing and manufacturing electrodes.

Integrated CAD/CAM software to design complex electrode geometries.

Streamlined processes, shift to higher quality, more complex tools.

A focus on electrode design and automation helps toolroom improve efficiency, reduce tooling costs and deliver higher quality products.

Based in Macomb, Michigan, custom injection molder and contract manufacturer PTI Engineered Plastics operates in a highly competitive industry. The company has built a reputation for excellence, standing out from its competitors with its dedicated 35-person, in-house toolroom. PTI engineers, designs, builds and maintains every mold used in its manufacturing processes for a diverse customer base, including medical, automotive, defense/aerospace and commercial/consumer products companies.

PTI recently took on a typical challenge: creating a “functional prototype” for an electric vehicle (EV) charging plug in just five weeks. The project involved intricate details and complex mechanical actions, with a production range between 1,000 to 80,000 parts. Despite the tight timeline, PTI quickly mobilized to tackle the project.

“The mold had complex tool actions for the slides, inserts and about 200 electrodes to produce. The customer shared their filling and cooling simulations with us to assess the part’s warpage. Using Cimatron’s morphing/bias, we then used windage to adjust the mold to account for the warpage. Adjusting details after the fact on a job like this is both costly and time consuming,” says PTI Toolroom Manager Chris Behring.

In the past, their EDM department would have been tied up for weeks. They would need to pull the electrode geometry, model the extensions and projections, add suitable base assemblies, machine the electrodes and manually key in four-digit numbers for over 200 electrodes for multiple locations.

“This design and build would have taken us 10-12 weeks in the past, but thanks to our designers’ expertise, the toolmmakers’ experience, the simplicity of the Cimatron system and the investment in EDM robotic automation, we were able to meet the deadlines and deliver a high-quality mold on specification,” Behring adds.

PTI knew it would be challenging for the toolroom team, but using Cimatron’s software to simplify the process, they were able to meet the customer’s requirements again. “We got it right with the first shot and met the drawing specifications,” Behring says.

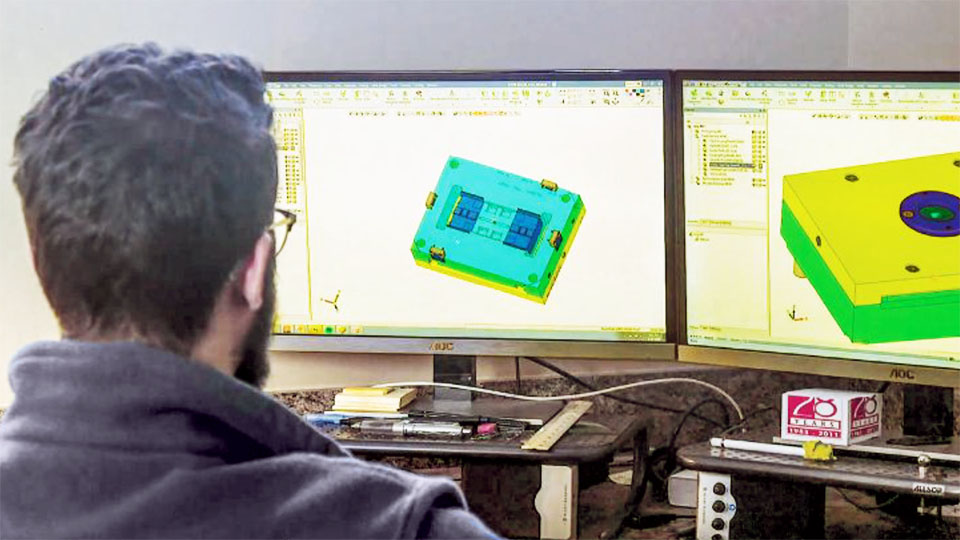

To tackle this challenge, PTI selected Cimatron’s integrated CAD/CAM software, taking advantage of its electrode design capabilities, which enabled the team to design and create complex electrodes with ease.

“Not too long ago, we had to do the tedious CAD work manually to create the electrode, blank and base. This involved tasks such as copying a set of surfaces to a new part, offsetting those faces for the 2D orbits or 3D overburn, extending, trimming, modifying, etc. It took a lot of time to model, program the tool paths and set up the holders. Then, we had to define the G-code to feed the sinkers. This process would take over an hour, and we had to repeat it for each electrode. Today, we use Quick Electrode to perform the whole process in less time while being more productive and accurate,” Behring explains.

Quick Electrode automates many of the repetitive functions used to design electrodes. It sets up the electrode assembly, maintains a color palette and standard height rules, uses standard and specialized solid and surface functions, and automates documentation for electrodes and electrode assemblies. Additionally, with EDM setup, it generates G-code for PTI’s sinker EDM.

PTI’s designers spearheaded the project, utilizing Cimatron to design the intricate electrode geometries needed. Despite their different levels of experience with CAD/CAM software, they were all able to use Cimatron CAD/CAM effectively. One of the main advantages of Cimatron’s electrode solution is its user-friendly interface and accessibility to users with varying skill levels. According to Behring, the software’s simplicity enables even less experienced users to operate it effectively.

“This has been crucial for us, as it enables our specialized talent to focus on design tasks while ensuring the electrode machining process remains efficient and accurate,” says Behring.

Cimatron software’s electrode extraction and design automation features allow the team to create the necessary electrodes efficiently, with a minimum number of steps. It automates many of the repetitive functions used to design electrodes.

“The streamlined electrode design process includes Extract, 3D Trajectory, Simulation and EDM Setup to guide our operators through the process. We simply select the shape (rectangular or cylindrical), adjust the burn location and pull the electrode,” says Behring.

The system creates and activates the new electrode assembly. The top-down workflow guides the operators through the creation of the electrode blank, burn body, surface/solid extension to base, holder, apply reference origin and copy or mirror to other cavities.

“Cimatron’s electrode solution was definitely a strong point for us. The quick electrode extraction and automated design capabilities have been a huge part of what we do at PTI,” says Behring.

PTI’s electrode automation has significantly influenced the company’s ability to handle other complex projects with tight deadlines. This automation includes four high-speed graphite machining centers fully dedicated to cutting electrodes, each with a vacuum system, 100% Erowa robot integration, three Makino CNC sinker EDM systems and two wire EDM systems.

The company prioritizes electrode automation out of necessity because it builds highly detailed jobs with hundreds of electrodes. Its investment in electrode automation, facilitated by Cimatron, has allowed PTI to significantly increase its production capacity and keep pace with customer demands.

“We have 2,500 sets of electrode holders for our robots, which might last four or five weeks before needing to be broken down,” says Behring. Cimatron’s electrode solution integrates seamlessly with PTI’s Makino sinker EDM machines. Before Cimatron introduced this capability, PTI’s programmers had to program the sinker machines manually, even after automating the electrode machining process.

“Now, we can take the electrode design from Cimatron and directly transfer it to our sinker EDM machines, eliminating the need for manual programming. This has greatly reduced the potential for errors and improved overall efficiency,” adds Behring.

PTI’s implementation of Cimatron and its focus on electrode automation have improved its mold building processes and significantly impacted its business performance. The company has streamlined its processes, reducing the number of tools built annually from 800 to under 300 while shifting focus to higher cavitation, more complex tools. This has enabled the company to better support its manufacturing operations, which have evolved to prioritize higher cavity, more intricate medical devices and disposable, highvolume, self-dosing drug delivery devices.

Implementing Cimatron has been a transformative experience for PTI. Prior to adopting Cimatron software in the early 2000s, the company relied on five different software packages.

Once we moved to Cimatron, we became five times more efficient. We eliminated translation time and file transfer errors while improving overall performance throughout the tooling process.

“It took me two years to determine Cimatron was the best fit for us for our entire mold build process. Using five different systems to quote, design, manufacture and build our molds cost us time and money. The cost of the disparate systems, the overhead of training the team on different systems, and the errors involved in transferring and translating data from system to system were prohibitive. However, once we moved to Cimatron, we became five times more efficient. We eliminated translation time and file transfer errors while improving overall performance throughout the tooling process,” Behring says.

With Cimatron as its foundation, PTI is not only well-positioned for future growth and innovation but also eager to explore new horizons. The company plans to venture into metal printing, adding to its five-axis machining capabilities and strengthening its commitment to continuous improvement and innovation.

PTI Engineered Plastics: teampti.com

WeForm, responding to growing customer demands, invested in a fully automated production cell integrating 5-axis HSC milling and Cimatron CAD/CAM software for efficient production of high-quality plastic and zinc die-cast parts across various industries.

Everstampi, a family-owned company in Misinto with more than 40 years of experience in plastics mold design, stands out for its innovation and focus on customer service, using CAD/CAM solutions from Cimatron to optimize the production process and ensure complex, high-precision molds.

Classic Tool & Die, leveraging Cimatron's advanced CAD/CAM software, achieved a 75% productivity increase and reduced its carbon footprint, while successfully tackling challenging die design projects and fostering innovation with automotive OEMs.

A focus on electrode design and automation helps toolroom improve efficiency, reduce tooling costs and deliver higher quality products.

Clips & Clamps Industries efficiently handles complex die designs and high-volume production requirements by leveraging Cimatron CAD/CAM software, which streamlines workflows, optimizes designs, and enables significant cost savings through material optimization and enhanced tooling capabilities.

The integrated CAD/CAM software package from Cimatron helps TK Mold & Engineering Inc. reduce translation errors, simplify the design process, improve shop efficiency, and shorten tool lead times.

Follow us on