This is where Cimatron shines. Especially for high-volume projects, I can quickly lay out an accurate strip for estimating, and by reducing a key dimension by one millimeter, we were saving 80,000 pounds of steel a year.

Since 1954, Clips & Clamps Industries has designed and manufactured high-quality stamped parts for the automotive industry. Based in Plymouth, Michigan, the woman-owned business specializes in progressive die stampings, wire forms, slideforming products, and automated welding and assembly. Serving major OEMs and Tier 1 suppliers domestically and internationally, Clips & Clamps prides itself on robust tooling designs that maximize production uptime.

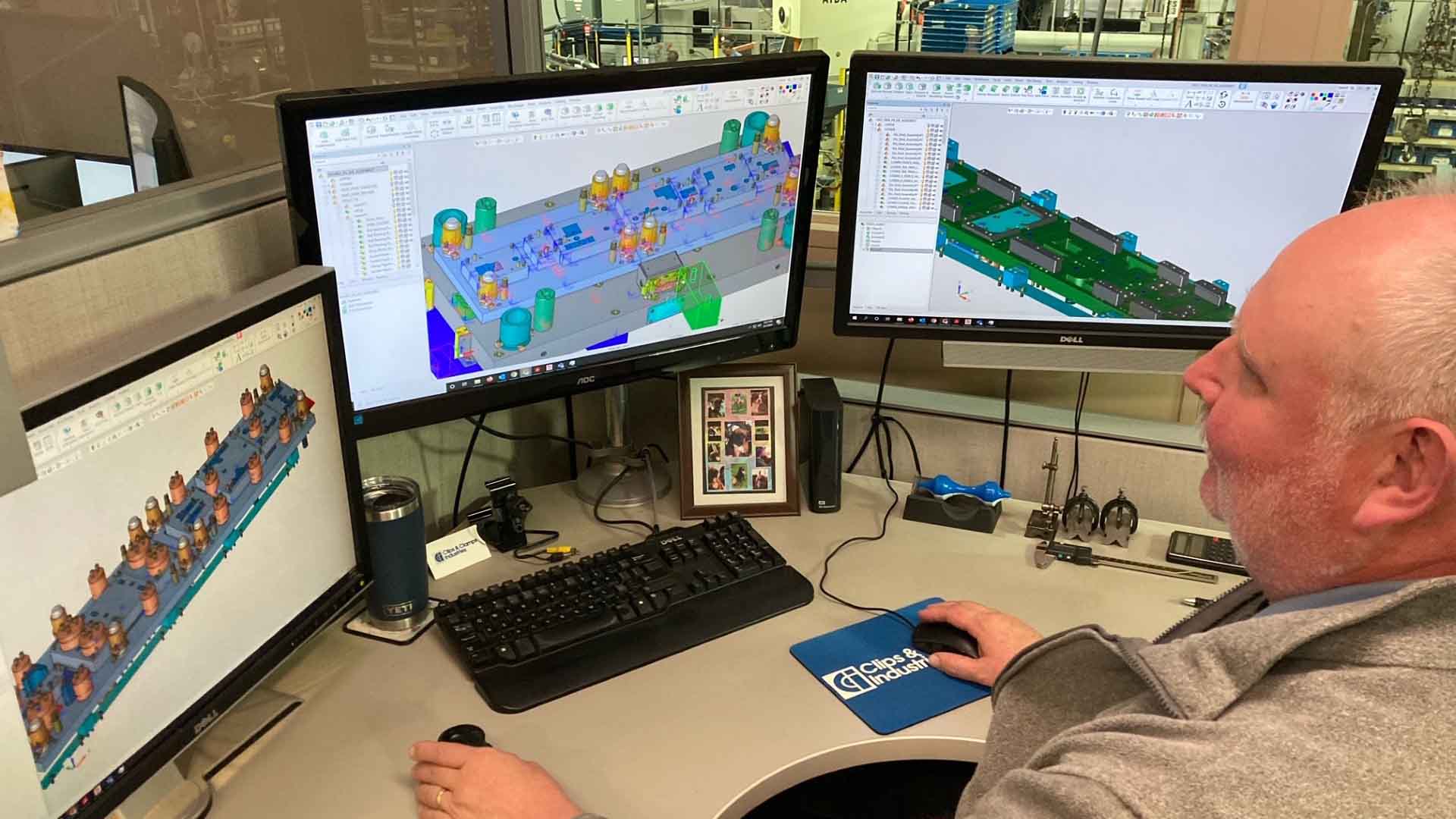

Faced with the need to efficiently handle complex die designs and high-volume production requirements, Clips & Clamps turned to Cimatron CAD/ CAM software. Leveraging Cimatron’s capabilities across the product development process — from quoting to design to manufacturing — Clips & Clamps has been able to streamline workflows, optimize designs, and deliver high-quality tooling to its customers.

Clips & Clamps is no stranger to the challenges of the demanding automotive industry. The company designs and manufactures large-volume, high-quality, progressive dies for increasingly complex parts, often made from advanced Gen 2 and Gen 3 high-strength steels that reduce weight without compromising structural integrity or safety. At the same time, the company faces intense pressure from its OEM and Tier 1 customers to reduce costs as much as possible.

One recent example that illustrates these challenges was a tie bar part made from 439-HPstainless steel. This material’s abrasive nature required special tooling considerations, including high-quality Vancron tool steels, custom punch designs, and specialty coatings. Meeting the part’s tight tolerances while optimizing production efficiency required expert design, precision machining, and rigorous testing.

Clips & Clamps relies on Cimatron CAD/CAM software across its product development process, including:

Effective quoting is critical for an automotive supplier like Clips & Clamps. Material costs can account for 70% or more of the total, so optimizing the blank size and strip layout is essential for submitting competitive bids while maintaining profitability.

“This is where Cimatron shines. Especially for high-volume projects, I can quickly lay out an accurate strip for estimating, and by reducing a key dimension by one millimeter, we were saving 80,000 pounds of steel a year,” said Matt Alholinna, Senior Designer, Clips & Clamps.

This kind of adjustment not only saves thousands of pounds of raw material but also directly translates into cost savings and helps the company meet sustainability targets by reducing the amount of steel required.

Cimatron streamlines the quoting process by providing fast, automated tonnage calculations, helping Clips & Clamps assess press requirements quickly. The software also allows designers to optimize layout, pitch, and blank size to maximize material utilization. These capabilities enable Clips & Clamps to respond quickly to customer RFQs while ensuring that quotes are accurate and competitive. By optimizing material utilization and press selection upfront, the company can protect its margins and win more business.

With its dedicated tooling design capabilities, Cimatron accelerates the die design process at Clips a& Clamps. The software’s extensive catalog of standard components allows designers to incorporate items like nitrogen cylinders quickly. “I can pull in all the component data within Cimatron when designing and put them right into the design,” noted Alholinna.

Parametric modeling enables rapid design iterations and simplifies ECO management. “When we get a revision to the part, maintaining all the constraints in the tool, I’ll actually bring in a secondary strip and work off that. This way, I’ve got the latest change, with constraints tied to it for future work,” Alholinna explained.

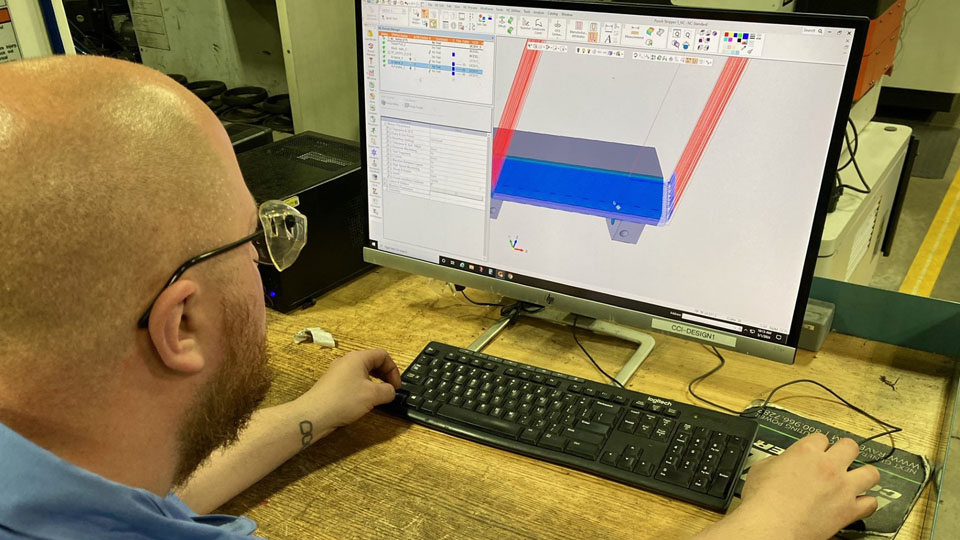

Cimatron’s integrated CAM capabilities have effectively revolutionized die machining at Clips & Clamps. “Matti [Alholinna] designs in Cimatron, and then we use the CAM portion in the toolroom, keeping it in the native software,” said Stephen Derosia, Tool Room Supervisor. “We’re not having any mix-ups, errors, or bad geometry issues.”

The company uses Cimatron for a range of machining operations, including milling, drilling, tapping, and wire EDM. “We use the CAM machining process in our mills. We use it for drilling, tapping, hard milling, profiling, and all that in our mills, and then we also use it on our EDM side,” said Derosia.

Toolpath simulation is another key benefit, allowing Clips & Clamps to validate programs before sending them to the shop floor. “Our operators simulate all the programs before we run them to the mills or the machines. We use the simulation software to check the toolpaths, ensuring the cutters aren’t doing any weird characteristics. It’s the same with the wire burners, making sure they’re on the right side of the line,” Derosia shared.

By leveraging Cimatron’s fully integrated CAD/CAM platform, Clips & Clamps has streamlined its die development process. Design data flows seamlessly to manufacturing, while powerful toolpath programming and simulation capabilities help optimize machining operations. This integration is vital to the company’s ability to produce high-quality stamping dies efficiently.

We’re not having any mix-ups, errors, or bad geometry issues. Matti designs in Cimatron, and then we use the CAM portion in the toolroom, keeping it in the native software.

By implementing Cimatron across its operations, Clips & Clamps has significantly improved efficiency and productivity. In many cases, the company has been able to slash its design time by half. “A lot of the jobs that used to take us four to six weeks to design, we can now knock out in half the time,” noted Alholinna.

Because the company uses the software for both design and manufacturing, data transfers seamlessly from engineering to the shop floor. Derosia shared, “Having Cimatron in both design and on the shop floor streamlines the whole process. We’re designing and doing the CAM programming in Cimatron, and it’s helped us reduce downtime and keep the presses running.”

Cimatron has also enabled Clips & Clamps to handle more complex geometries and tougher materials. “Back when we were using AutoCAD, we were getting more complex geometries. That’s when we decided we needed something geared for 3D. Cimatron’s formability analysis tools have proven especially valuable as we take on jobs with advanced Gen 2 and Gen 3 high-strength steels and other challenging alloys,” Alholinna shared.

Cimatron allows Clips & Clamps to confidently work with Gen 2 and Gen 3 steels, which offer comparable formability to their Gen 1 counterparts but with much higher tensile strength. With better energy absorption, Gen 2 and 3 steels allow for improved crash performance while facilitating greater design flexibility and potential cost savings.

In addition to driving internal efficiency, Cimatron is helping Clips & Clamps Industries deliver greater value to its customers. Improved quoting accuracy, optimized designs, and streamlined manufacturing translate into higher-quality tooling and more competitive pricing.

Cimatron is one of the most important tools in our toolbox, and it has served us well. It’s allowed us to be more precise in quoting and speed up the design process.

WeForm, responding to growing customer demands, invested in a fully automated production cell integrating 5-axis HSC milling and Cimatron CAD/CAM software for efficient production of high-quality plastic and zinc die-cast parts across various industries.

Everstampi, a family-owned company in Misinto with more than 40 years of experience in plastics mold design, stands out for its innovation and focus on customer service, using CAD/CAM solutions from Cimatron to optimize the production process and ensure complex, high-precision molds.

Classic Tool & Die, leveraging Cimatron's advanced CAD/CAM software, achieved a 75% productivity increase and reduced its carbon footprint, while successfully tackling challenging die design projects and fostering innovation with automotive OEMs.

A focus on electrode design and automation helps toolroom improve efficiency, reduce tooling costs and deliver higher quality products.

Clips & Clamps Industries efficiently handles complex die designs and high-volume production requirements by leveraging Cimatron CAD/CAM software, which streamlines workflows, optimizes designs, and enables significant cost savings through material optimization and enhanced tooling capabilities.

The integrated CAD/CAM software package from Cimatron helps TK Mold & Engineering Inc. reduce translation errors, simplify the design process, improve shop efficiency, and shorten tool lead times.